-

Menu

-

Home

-

NYC RF Scans

-

RF Devices

-

TheLab

-

Downloads

-

About

-

RF Tools

-

PinkNoiseFlashlight

-

BetaPages

-

Downloads

-

Item

-

IMD or Intermodulation Distortion occurs when two or more transmitted frequencies become non-linear. It is not necessary to understand this concept at this time. It is more important to understand when IMDs occur and how to prevent them from occurring or avoid them. Lets look at some practical examples of when IMDs occur.

One very common causes of IMD occurs when you have two of more microphones very close to each other. This commonly happens when you set out microphones on a table, or the top of a rack ready to be used. We are going to do some testing to determine the impact of this process on the generation of IMDs.

The Test:

To measure the IMD’s Created by two Shure UR2 handheld microphones in four different scenarios.

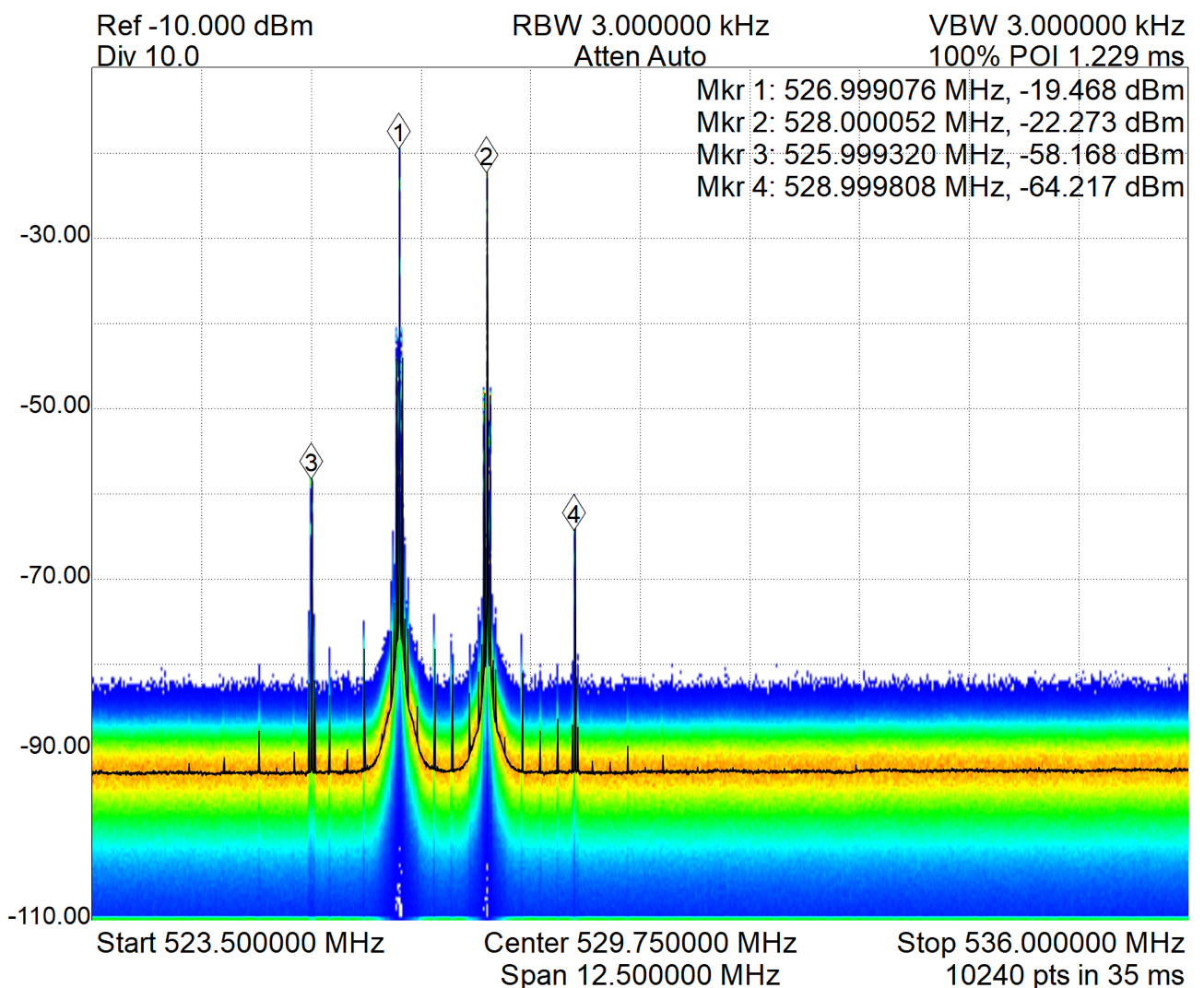

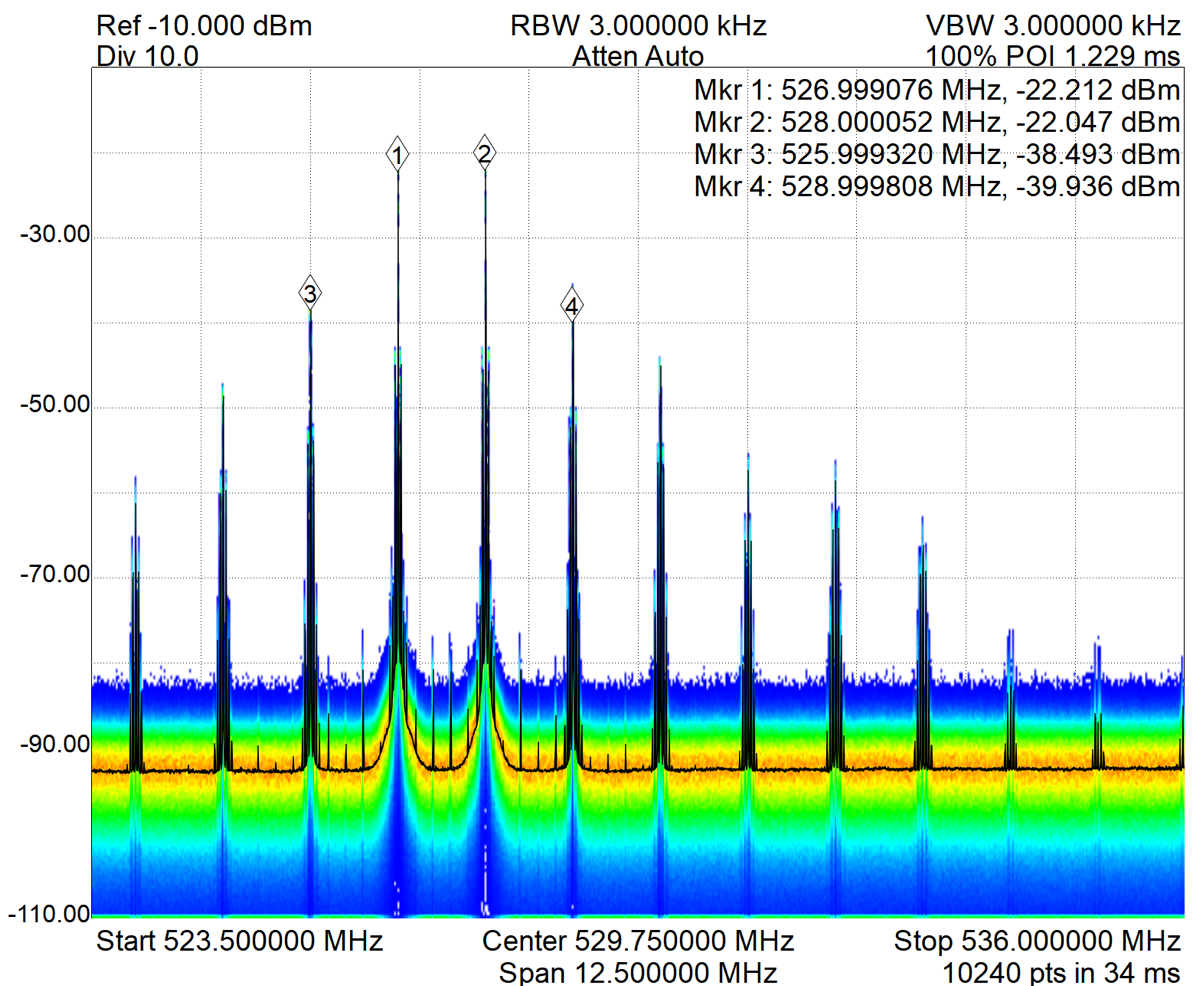

1. Both microphones on table touching at the capsule end and the battery compartment end

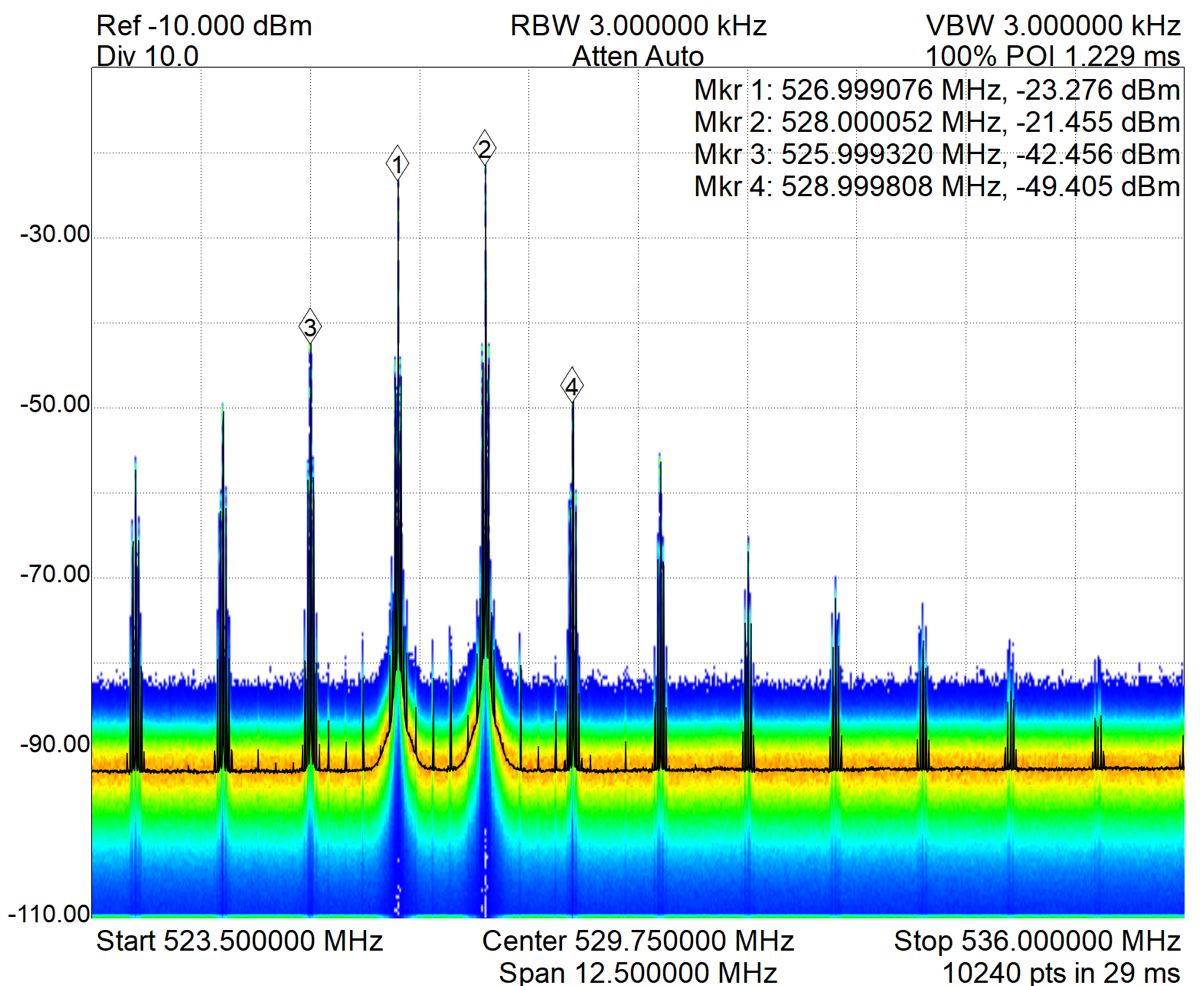

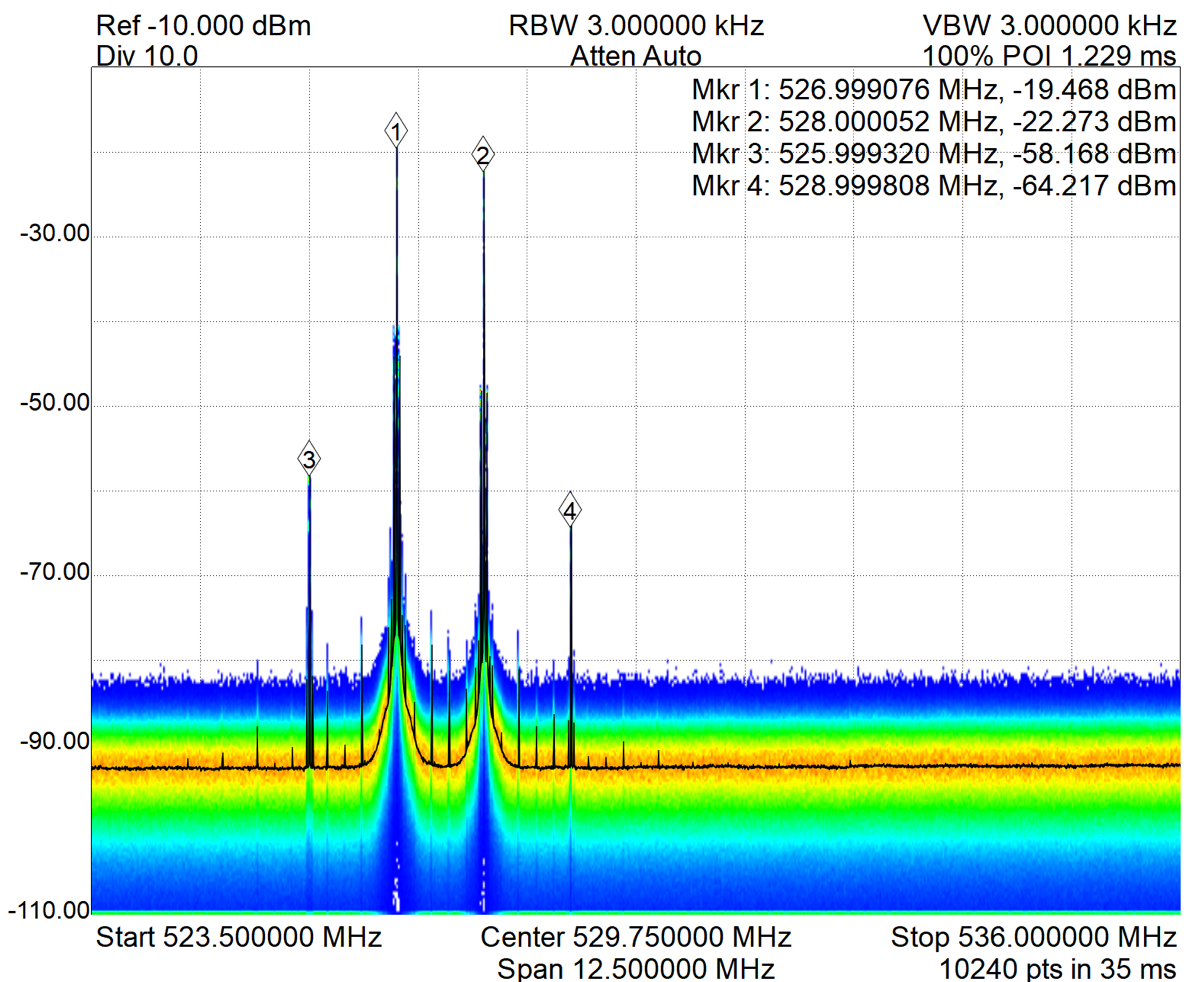

2. Both microphones on table touching and facing opposite directions with capsule end of each microphone touching antenna end of the other microphone.

3. Both microphones on table 6 inches apart and Parallel to each other.

4. Both microphones on table 6 inches apart and Parallel in aluminum foil Drip Pans (Weber #6417).

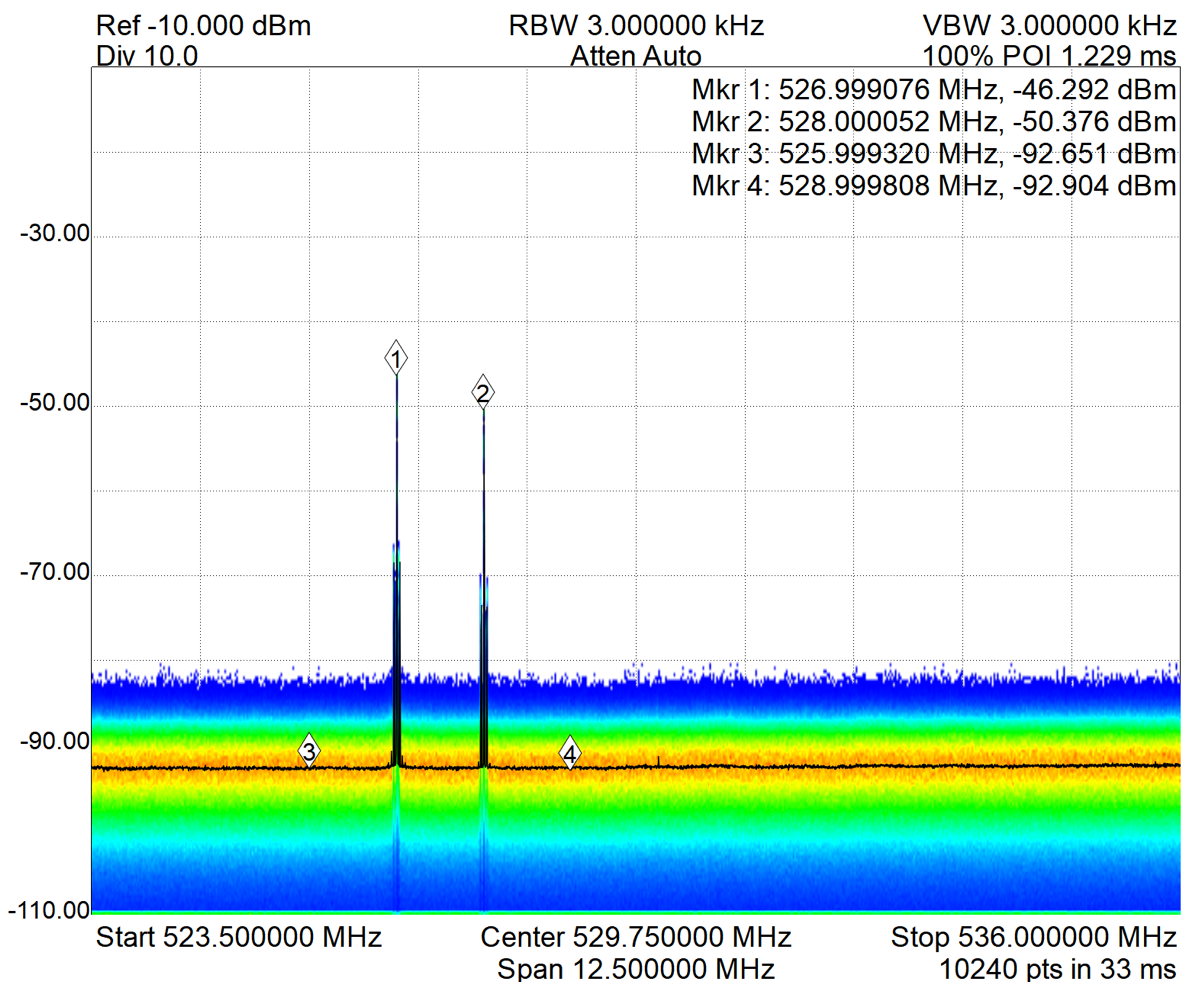

All four tests use the same two microphones and are tuned to the same frequencies for each test. The microphones are set to high power and the antenna for the scanner is a wide band dual dipole 1 meter above the microphones oriented in phase with the microphones.

Acceptance Criteria:

1. the average of the 2 tone3rds is less than half the power in dBm of the average of the primary tones in relation to the noise floor.

2. Neither of the 2tone5ths are more than 10dBm above the noise floor.

Observations: 2tone3rd IMD average is greater than half the average dBm of primary tones. 2tone5ths IMD are greater than 10dBm above the noise floor

Observations: 2tone3rd IMD average is greater than half the average dBm of primary tones. 2tone5ths IMD are greater than 10dBm above the noise floor.

Note: These results were not as expected and the IMDs are of higher power than in test #1. This method is often seen in practice and it is commonly assumed that this method would reduce the generation of IMDs testing does not support this.

Observations: 2tone3rd IMD average is less than half the average dBm of primary tones. 2tone5ths IMD are less than 10dBm above the noise floor.

Observations: 2tone3rd IMD average is less than half the average dBm of primary tones. 2tone5ths IMD are less than 10dBm above the noise floor.

This scenario produces the most desired results and should be best practice with all handheld and belt pack transmitters.

The use of aluminum drip pans (Test#4) produced practically no generation of IMDs and should be considered the pest practice when staging microphones.

Having the microphones on a table 6 inches apart was acceptable by our acceptance criteria but if a scenario existed where avoidance of 2tone3rd IMD was not included in to frequency coordination calculation problems with interference could be experienced. The distance of 6” was a minimum distance that should be used placing the microphones further apart will produce more favorable results.

Both scenarios where the microphones were in physical contact with each other (test#1 and test#2) produced IMDs at a levels that did not meet the acceptance criteria. The use of microphones in these two scenarios will likely cause interference with other devices even if a proper coordination is performed.